Never Fall Tension Shower Rods hold more weight than traditional tension rods, up to 50 lbs. Simple to install with no tools required. The end cap rollers use a patented CAM lock technology to create superior tension.

A new way to generate tension

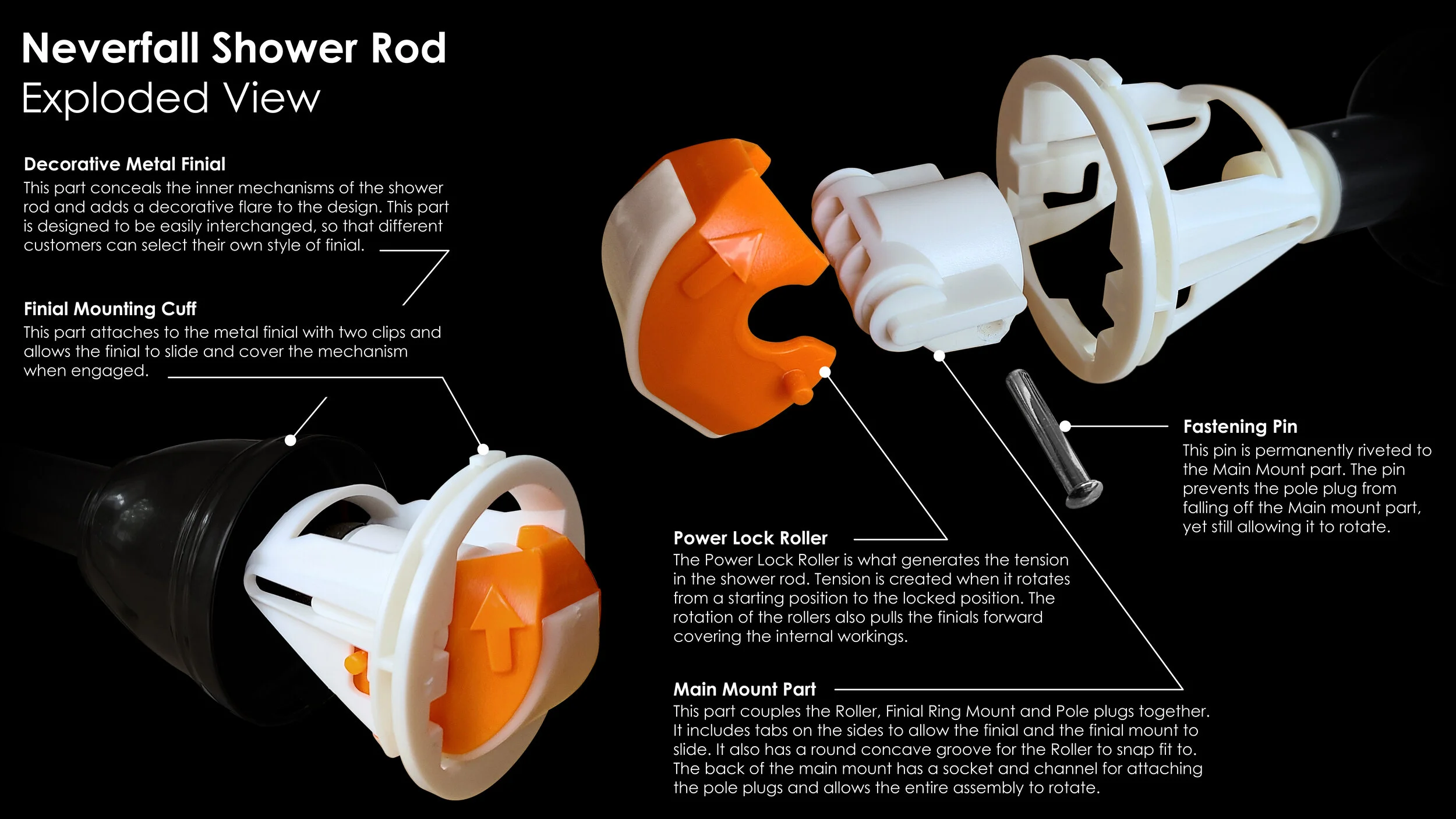

Power Lock Technology is what generates all the tension in the Never Fall Shower Rod. Each endcap houses a Power Lock Roller inside. The Rollers create the grip and tension in the rod by converting downward pressure into outward tension.

The Rollers are CAM mechanisms that create mass amounts of tension when moved from their start position to their locked position. When both rollers are engaged, they can create up to 75lbs of outward pressure.

As the Rollers engage, the decorative metal finials simultaneously slide forward towards the shower wall. This action hides the orange rollers and gives visual feedback to they user that the shower rod is properly installed.

Design Highlights

This Shower Rod Is a Patented Technology

I was tasked to design an extremely strong tension rod, with simple installation and would require no tools or screwing into tile. I started by looking at all the current shower rods and the mechanisms they use to generate tension. I found that although strong enough to hold up a shower curtain, the outward tension generated was lacking and the installation could be simplified.

I started looking at other mechanisms that could generate outward tension. After much research and several concepts, I fabricated a prototype that used CAM mechanism rollers on ether end of the rod. These rollers, when downward force was applied, pushed on to the wall surface with equal or in some cases multiplied force. By simply pulling down on the rod the opposing CAM mechanisms create tension and lock into place. We called this innovation Power Lock Technology.

Since a technology like this had never been used on a tension rod, we patented the final design.

Using pure tension to hold up to 50 lbs. No screws or drilling required.

End Cap Assembly Process

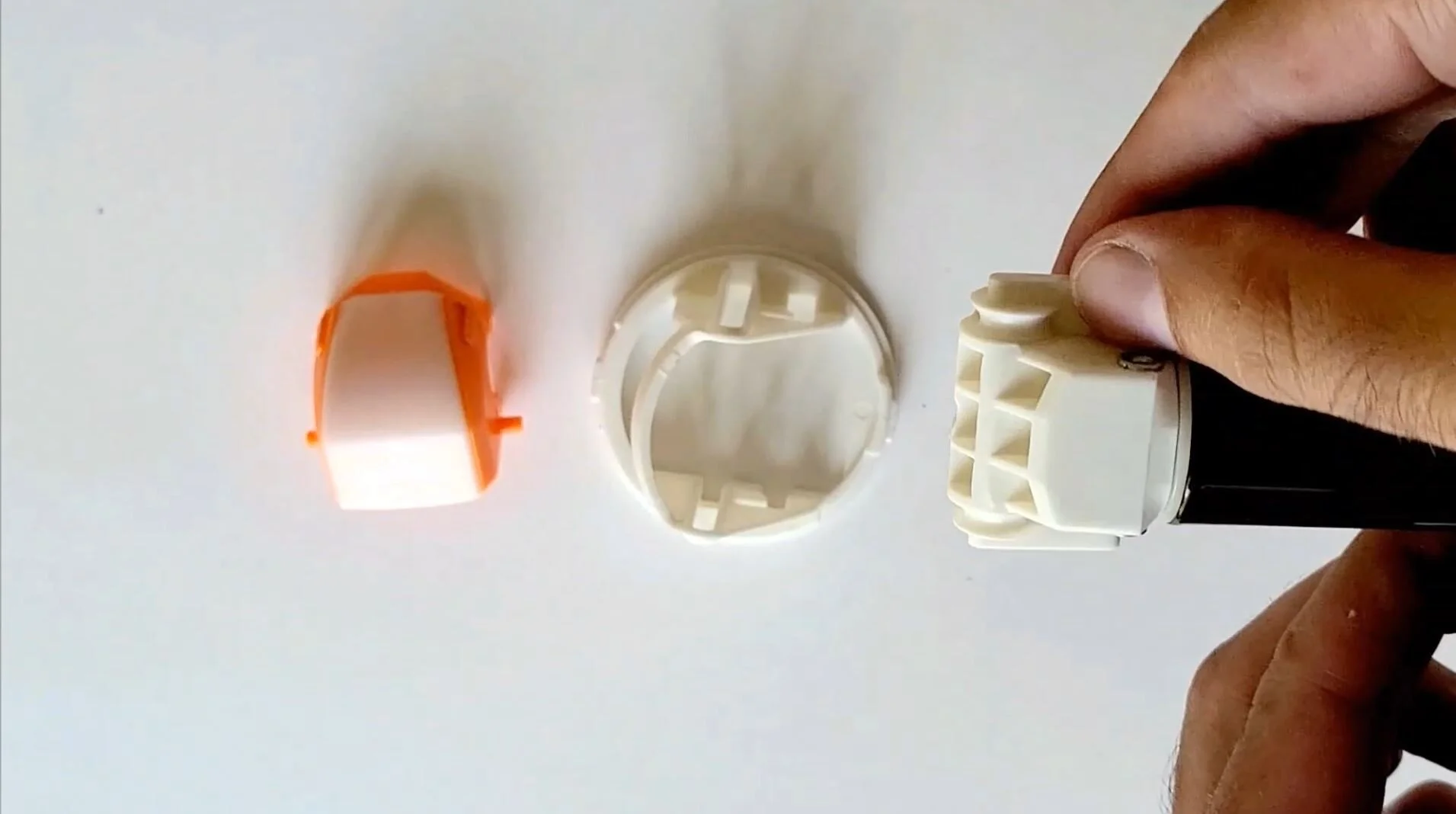

Snap Together Assembly

All plastic components were designed to snap together for easy assembly. Since this shower rod is more complex than standard rods, this easy assembly method allows for fast manufacturing. All the components on this shower rod I personally designed, tested and collaborated with factory technicians to manufacture.

Never Fall Shower Rod: Testing

After developing this shower rod, we quickly realized that it could hold more weight than any other tension rod on the market. I was asked to design a testing rig that would allow us to measure how much weight the shower rod could hold in a controlled way. I developed this testing rig that would allow us to test the rod consistently and incrementally add weight until the rod fell.

This testing rig allowed us to better review design improvements to the Never Fall Shower Rod and check production samples from the factory to ensure proper performance. It also later allowed us to substantiate our claim of; “Holds up to 50lbs.” Because this test method was far more accurate than the current tension rod testing protocol, the testing rig and testing protocol I developed was later adopted by Bureau Veritas Consumer Products Services, as the official test for all consumer tension rods.